Achema 2024: Safe processing for demanding products with COMBER machines

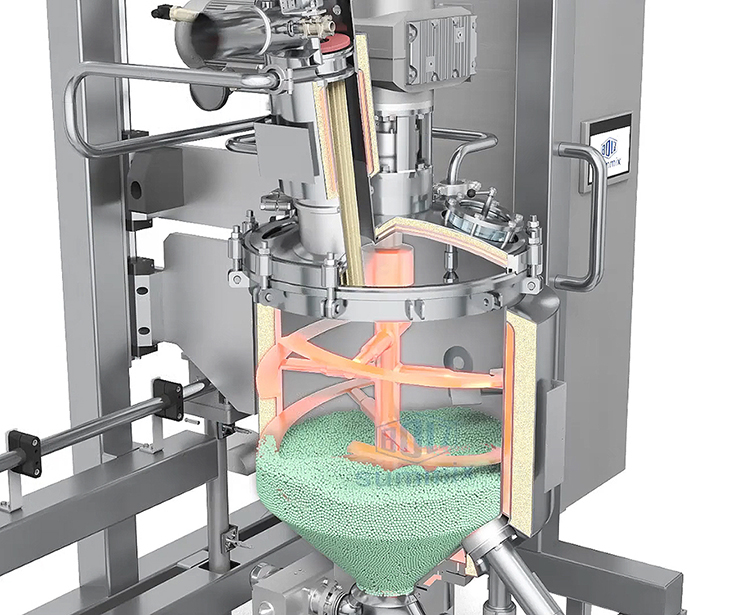

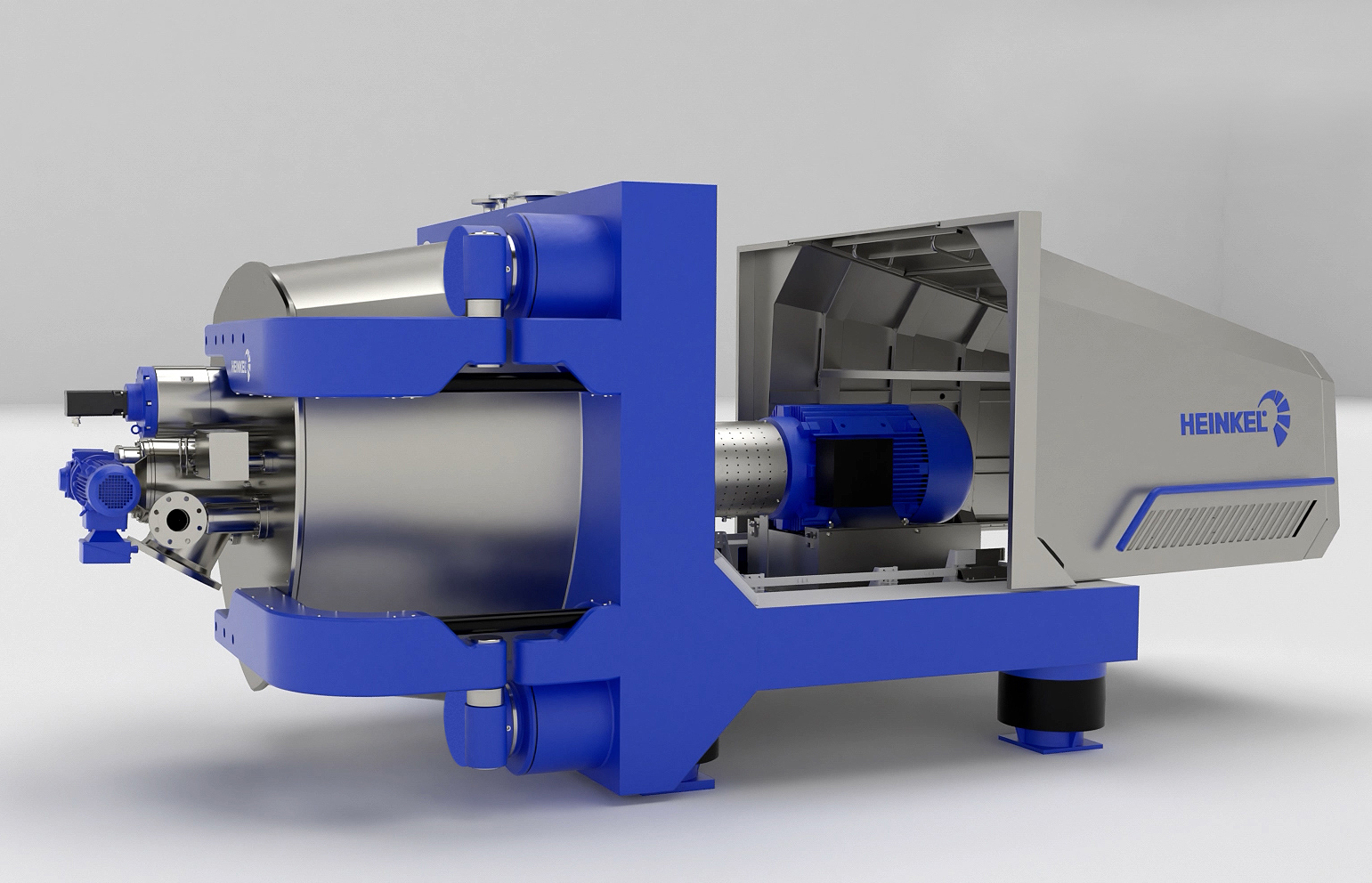

From 10 to 14 June 2024, ACHEMA 2024 will take place in Frankfurt am Main. ACHEMA is the leading trade show for the process industry with a global signal effect for the chemical, pharmaceutical, biotechnology, energy and environmental sectors. At the joint booth C49 in hall 6.0, the HEINKEL Drying and Separation Group with its brands BOLZ-SUMMIX, COMBER, HEINKEL and JONGIA will be presenting innovative product highlights and tried-and-tested solutions.