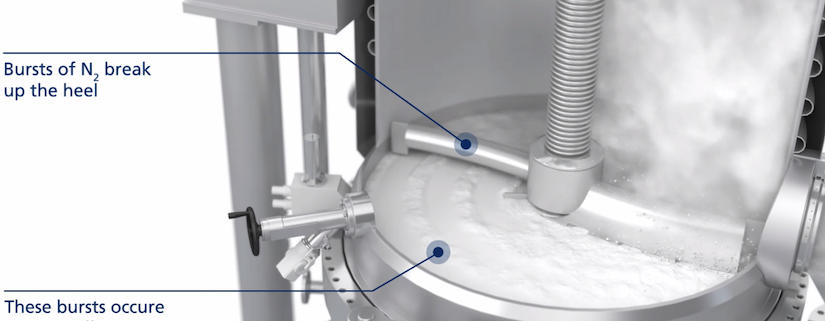

COMBER shows efficient Heel Break System for heel-free product discharge at POWTECH 2023

COMBER is presenting at this year’s POWTECH in Nuremberg, how to achieve the highest product yield with the modern Heel Break System for the Pressofiltro® filter dryer. At the joint booth of the HEINKEL Drying and Separation Group in hall 4, booth 319, the industry specialist is showcasing parts of the system on a pilot scale.