COMBER: celebrating 60 years!

Article ICP magazine, rivista dell’industria chimica (English translation below)

https://www.icpmag.it/ultimo-numero

For 60 years, COMBER has been a leading supplier of Nutsche filters, filter dryers and batch type vacuum dryers for pharmaceutical and chemical production. It is indeed from 1960 that COMBER, now part of part of HEINKEL Drying and Separation Group (HDSG), offers its customers high quality machinery, all Made in Italy.

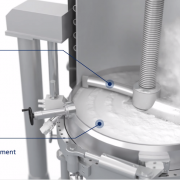

Based in the industrial area of Milan, COMBER Process Technology produces complete drying and filtration lines for the particular needs of the pharmaceutical and fine chemical industries, becoming over time a leading supplier of Nutsche filters, filter dryers, batch dryers and vacuum dryers. This type of equipment is used in the following cases:

- Batch-type solid / liquid separation

- Efficient washing of the filtered cake, including re-slurry

- Vacuum drying of the high-performance product

Since 2010 COMBER has become part of HEINKEL Drying and Separation Group (HDSG), which includes three other companies: BOLZ Process Technology GmbH, HEINKEL Process Technology GmbH and JONGIA N.V..

With over 130 years of experience, HDSG offers innovative and dependable solutions in filtration and centrifugal technology, nutsche and vacuum drying and mixing. This international group boasts one of the most complete product ranges for the chemical, pharmaceutical, fine chemical and food industries. COMBER has its headquarters in Agrate Brianza (MB) and the department of production and assembly in Carugate (MI).

A high-quality production

Founded in 1960, COMBER (the name derives from the acronym “COstruzioni Meccaniche BERramasche”) has a long history behind its success. They are a supplier of Nutsche filters, filter dryers (Pressofiltro®) and discontinuous vacuum dryers, like Turbodry® TD, Condry® TDC, Pharmadry® PH and Termomix ® TM (see Table). In recent years COMBER has developed the following technologies:

- Technologies to reduce exposure of operators to the product while unloading the equipment (integrated

discharge in the glove box) - Solutions to reduce the quantity of residual product in the equipment (Heel Break System)

- Complete lines, including solvent recovery, heating systems, vacuum units and integrated automation

- Execution of validation protocols and tests with placebo

- Sterile lines with glove box (sterilization with steam or hydrogen peroxide)

In support of API manufacturers

Giovanni Bellini, CEO of COMBER Process Technology, says: “COMBER’s attention to end users plays a central role. We study specific customer requests (URS), make offers, negotiations, contracts, sending of approval drawings and specifications techniques, construction, assembly, testing, FAT, delivery, assembly and start-up. COMBER directly follows all phases, from the initial offer to the start-up on site.

Since most of the customers are active pharmaceutical ingredient manufacturers (API), the plants supplied are subject to strict controls by the FDA or similar national authorities (AIFA in Italy). It is therefore essential to provide these bodies with all the necessary documentation and certification. To ensure total traceability / certification of materials and all the stages of production, Comber maintains total control as well as on projects, drawings, etc., as well as on the purchase of all raw materials, sheet metal cutting, processing, subcontracting only the construction of the “vessel”; even the validation of the equipment by inspectors (Lloyds, TÜV, etc.) are managed directly. Once all the components are received, the assembly is performed, tested and subjected to FAT (Factory Acceptance Test) internally.

A “Business Model” based on people

Since 2010 COMBER has implemented a business model with its partners which ensures flexibility and rapid adaptation also during these difficult times. While companies in the world go into debt to repay monthly installments for financial loans and bonds, COMBER has achieved financial independence with levels of minimum debt that show our customers that their payments are not used to cover other debts, but they are directly related to their equipment. Moreover, warehouse management and close relationship with suppliers are important assets of which COMBER, after years of collaboration, is rightly so proud.

From preventive maintenance where it offers a different automation, to the Engineering Business Partnering approach, COMBER helps its customers with the most suitable equipment according to their needs, minimizing their OPEX impact.

Human resources are very important for COMBER: for this reason, the company has never stopped constant training and onboarding of new and talented willing candidates to be part of this world. Coming from different sectors and countries, COMBER is also proud of its diversity and inclusion policy. The entire range of COMBER products, including CMR projects (COMBER acquired the logo and the drawing of the company CMR, another Italian supplier with a long tradition in pressure vessels and process equipment manufacturing), are an important resource that guarantees our customers full continuity in terms of service and spare parts.

The engineering team is open to any type of customization, so that each machine is tailor made. For this reason COMBER is able to follow its customers and help them define the best solution, the one that best suits their needs.

Online FAT support

In the first months of 2020, COMBER obtained the ISO 45001: 2018 Safety Certification for the Agrate Brianza (MB) plant, in addition to ISO 9001. In addition, during the lockdown, the company’s after-sales and service supported its customers remotely all over the world, carrying out remote automation and FAT services. Thanks to the functional and transversal development and its experience, COMBER was able to enter the world of B2B remote communication with customers very quickly and successfully, offering them webinars and training courses.

Due to the Coronavirus emergency, COMBER has created an online communication system in which customers can obtain first-hand live FAT experience through technology, interacting step by step with the Project Manager during the test protocol.

Interview ICP magazine with COMBER’s Managing Director Giovanni Bellini

BELLINI (COMBER):

“WE NEVER STOPPED”

COMBER is a 60-year-old company, very proud of its products and experience gained over the years. Every employee is very proud of what is being done and realises the importance of one’s work for the whole sector. We asked Giovanni Bellini, CEO of COMBER Process Technology, a few questions via Teams, too.

In the last weeks, COMBER’s activities have never stopped. How did you deal with this difficult period?

“The pandemic came like a storm, it has changed our habits in a few days and has put a severe test to our ability to always have everything under control. We had to reinvent our way of working and communicating. Since the beginning of March, the activities that can be done in the office, have been transferred without any problems to remote working. Maybe Comber has been one of the first companies that blocked all interventions, external activities and the entry of suppliers already on 25 February. We preserved the Engineering team which came back to the office for a week only to recover documents and papers, and then went back to work from remote or from home offices.

The plant remained open until March 12th, then was closed due to the impossibility to find Personal Protection Equipment such as masks and gloves: we have therefore decided to close, in compliance with the decrees issued by the government. After calling an external company for sanitizing (and after completing paint jobs) we are back on track since April 14. In fact, we have always kept the projects up and running, we only stopped the workshop until safety protocols could be implemented.”

How did the working organization proceed during these complicated days?

“For the delivery and commissioning of our plants we were used to do everything on-site, with protocols, in teams of 2/3 people. Then we were forced to adapt ourselves to transfer data, photographs and videos through online platforms. Within a few weeks, we have already delivered three installations.

For a well-known German company, we made an SAT from remote: the machine had already been delivered but instead of the usual intervention of our technicians on site, it was our customer who managed the work, following our instructions from remote with videos and photos: it took a week, but in the end the plant has been successfully installed. In fact, we have turned commissioning from hours on-site into hours of online assistance.

Also the staff responded remotely very well and I must say that this mode is very satisfying. We even acquired an order in mid-March, the worst period in the pandemic, managing everything remotely without ever seeing each other face to face. However, the first week back in Comber, we preferred to stop and evaluate the situation through conference calls, in order to organize and define the delivery methods.

The performance is good, but not exceptional. Let me explain: “If the technical office on-site usually does a job in 100 hours, with this system it takes 120/130 hours”. The standard is easier to manage, while for a designer it is a little more complicated to make certain decisions from home. On workshop level there is no choice: either to go or to close. At the reopening of the plant we managed the staff better, implementing all procedures: temperature detection, separate changing rooms, masks etc.”

How is the pharmaceutical and fine chemicals market changing from your point of view?

“It is clear that the pandemic is accelerating the trend, which was already underway, to bring back to Europe a part of the production of active ingredients that had been relocated to China and India in the past years. High value-added productions have already returned, and we have received many requests by Italian companies in the past two months, who are considering bringing back this type of production. This trend should give in the short / medium term some air for breathing to the sector of equipment and plant production in which Italy is one of the key players.

Users feel the need to have production lines closer, in factories which are easier to control. This should give us some peace of mind in the coming months and room for development. If you ask my personal opinion, I’m pretty confident that the API sector will still have a little return in the coming years, not so much in new products but also in existing ones. This should bring a recovery compared to the difficulties encountered in the period 2014/2015.”

Can you tell us about some particularly significant recent accomplishments?

- “For the past couple of years, applications have been increasingly concentrated on cannabis in the pharmaceutical field, for applications in the treatment of epilepsy and Parkinson’s. The first industrial plant is being built in England and Comber supplied two 3600 l dryers for one of the key steps of the project. The production process starts from the leaves which are already triturated, followed by decarboxylation (where we have mounted our equipment, used as decarboxylator), then the extraction is carried out.

An active principle is isolated, as approved for care in the USA by the FDA. We are confident of a market development, now partially blocked by the legislation (in America, for example, it is not possible to transport it in some states), but hemp is a very strong promising sector. We were among the first suppliers of equipment in this area and this should give us an advantage based on the acquired experience. - Another important application for us is the production of peptides, also used in cosmetics, where a sort of filter is used. It is a liquid product and in the phase of reaction the filter cloth is used as a substrate.

The catalyst, kept in suspension, activates the reaction, the liquid is then discharged and the catalyst is reused until it is exhausted and is then downloaded as a solid product. So it’s a filter that promotes a catalysed reaction. It’s about a niche sector, where we are well positioned. Because peptides are special products made with specific details, customization is important. This is a market that gives very good contribution margins. - In addition, we have created and launched for the Canadian market perhaps the largest vertical Turbodry®, Comber’s flagship equipment: 10,000 liters useful capacity with a shaft power of 170 kW.”

What are COMBER’s strategic objectives in the coming months?

“As already said, by accelerating the activity remotely, the pandemic forced us to review our strategies, especially for remote assistance, made necessary by not being able to go there personally. We have started working again on-site by customers in Lombardy, whereto it is possible to travel by car and do the intervention within a day.

We are trying to develop “packages” for the replacement of old machines with new ones, or revamping of existing ones, trying to sell hours of intervention remotely, doing online training, in order to intervene on the field only occasionally and only for special activities.

The problem is that while everyone is accepting to pay for travel without blinking, remote intervention, which requires personnel and hours of support, is thought to be for free. We need to change our mentality: it is not trivial to be able to “sell” our technicians’ online business. We are also working on assistance activities. In this period in case of necessity it was not possible to send for example spare parts or go on the field. It is therefore necessary to rethink traditional management, the relationship customer-supplier. Diagnostic programs could help in providing information to allow us estimating the needed spare parts: everything must be rethought with predictive maintenance reducing urgencies to a minimum.

Customers are bringing the production back home from “delocalisation”, because we must not forget that India and China need to improve their technological level, and Comber will play an important role in helping customers in this process.

We are trying to create an intermediate management phase for younger professionals (30/40 year olds) who can become the future of Comber in the next 15 years, and therefore give operational continuity over time.”