COMBER shows efficient Heel Break System for heel-free product discharge at POWTECH 2023

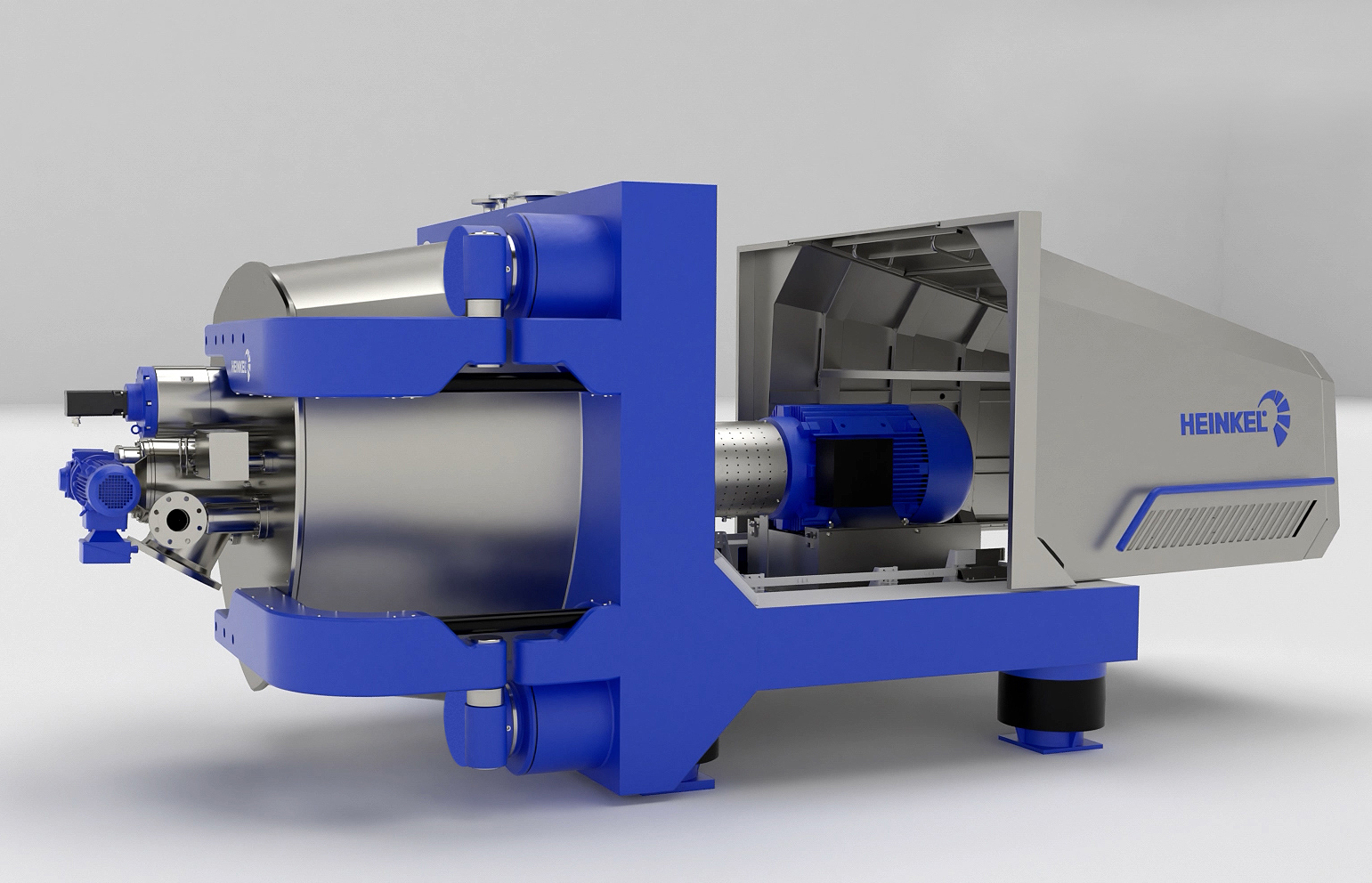

At this year’s POWTECH, COMBER will present how to achieve the highest product yield with the state-of-the-art Heel Break System for the Pressofiltro® Filter Dryer and will show parts of the system on a pilot scale. In addition, the company will demonstrate a solution for sample taking, even with process containers under vacuum. It can be used universally for COMBER’s broad product portfolio for the chemical, fine chemical and pharmaceutical industries.

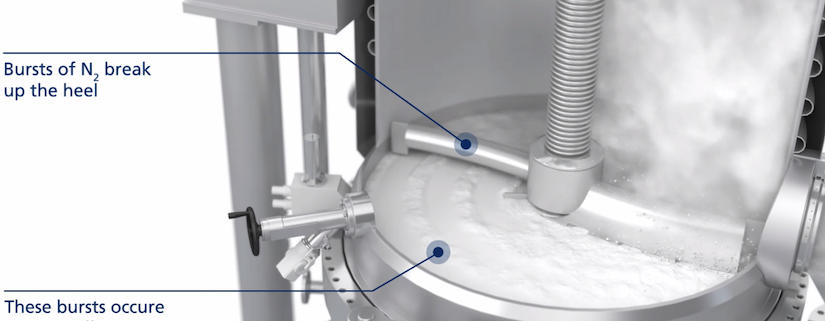

The Heel Break System breaks up the heel remaining after the product discharge, thus achieving a heel-free product discharge and the highest possible yield of the valuable product. By pressurising the multilayer filter plate with bursts of nitrogen, the heel breaks up and is discharged by the agitator. This is particularly effective in combination with the Whirl Snake Turbine, which uses nitrogen to blow any product remaining on the filter plate towards the discharge port.

The mixing shaft and the rotating nozzle head, rotating at the same time, ensure that all areas in the vessel are covered and the remaining product is completely removed. As an alternative to manual emptying via Glovebox, the COMBER Heel Break System enables a contained and automated process cycle. This increases both the efficiency of the process and the safety for product and operator. Additional versions are optionally available, such as a version with directed solvent counter current which significantly reduces the sedimentation of the solid in precipitation. The Nutsche filters and filter dryers are available for multipurpose applications, in ex-design as well as with CIP and SIP functions, depending on requirements.

COMBER sampling valve to ensure product quality

At POWTECH 2023, COMBER will also present a sampling valve that enables the safe removal of solid or liquid samples, even under vacuum. These representative samples are used for product monitoring and ensure product safety and quality. The sampling valves are flexible in use and have a bayonet locking, flange connection or triclamp arrangement. The solution is available for the COMBER Pressofiltro® Nutsche Filter or Filter Dryer, the Pharmadry® Paddle Dryer, Condry® Vacuum Dryer and the Turbodry® Vacuum Pan Dryer.