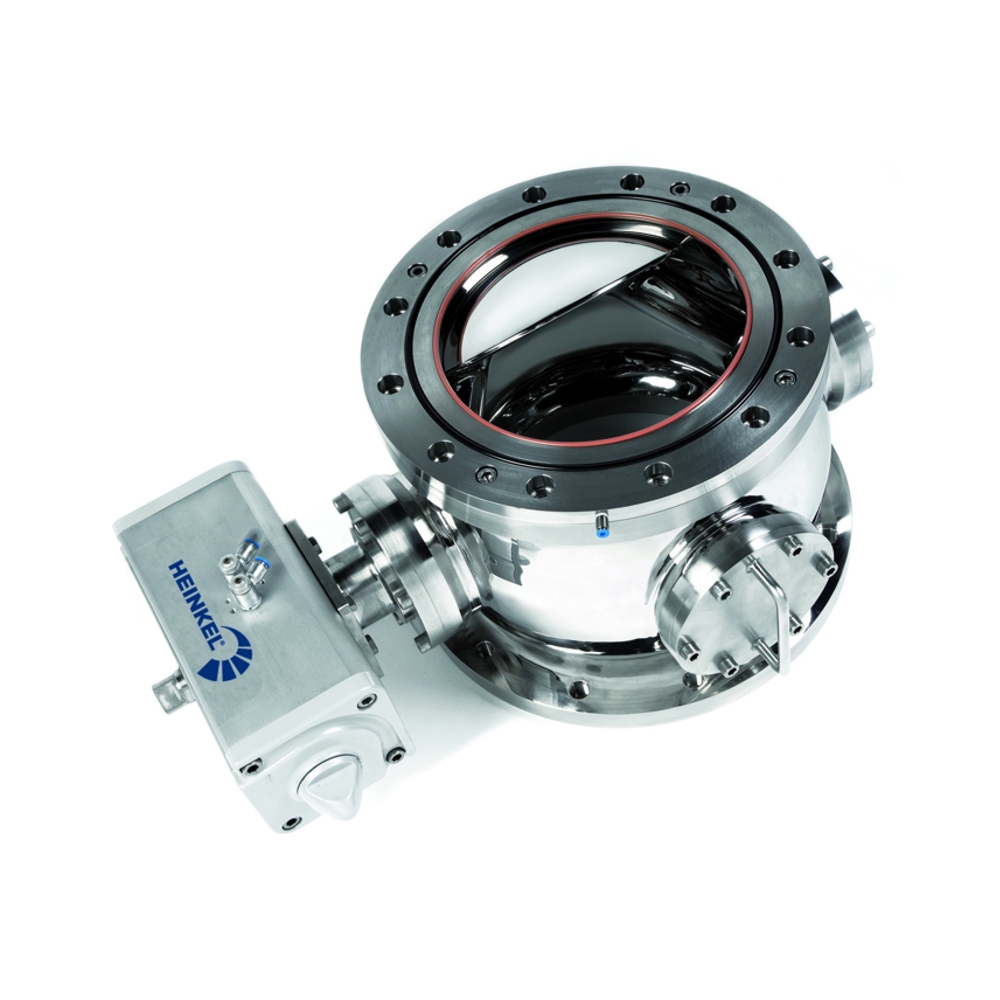

Ball Segment Valve

BSV Series DN 100 – 400

The Ball Segment Valve, BSV for short, is the result of a development of an innovative valve for pharmaceutical and fine chemical processes. For a wide range of solids applications, it is the preferred valve for process equipment like vacuum dryers, reactors or centrifuges as both as inlet and discharge valve.

Even if products are not free flowing, have an abrasive effect or have moist and adhesive properties, the Ball Segment Valve is the right choice as a reliable, vacuum and pressure-tight process valve. The internal corner-free and edge-free housing does fullfill your cGMP requirements and leaves the ball segment sufficient space to move clear of the product flow path when opened.

A reactor agitator or mixing tool can be designed to move within a few millimetres of the Ball Segment Valve virtually eliminating dead-space in the process area. Besides the standard flanges, the BSV can be equipped with tailored and non DIN flange connections to suit most existing reactor vessels.

Inflatable seal

High demands in terms of vacuum and pressure tightness are easy to achieve by retro-fitting our innovative sealing system in existing ball segment valves.

The special geometry of the inflatable seal enables long-term, reliable sealing against solid, liquid and gaseous media. There is a wide range of seal materials available.