Industrial Centrifuges

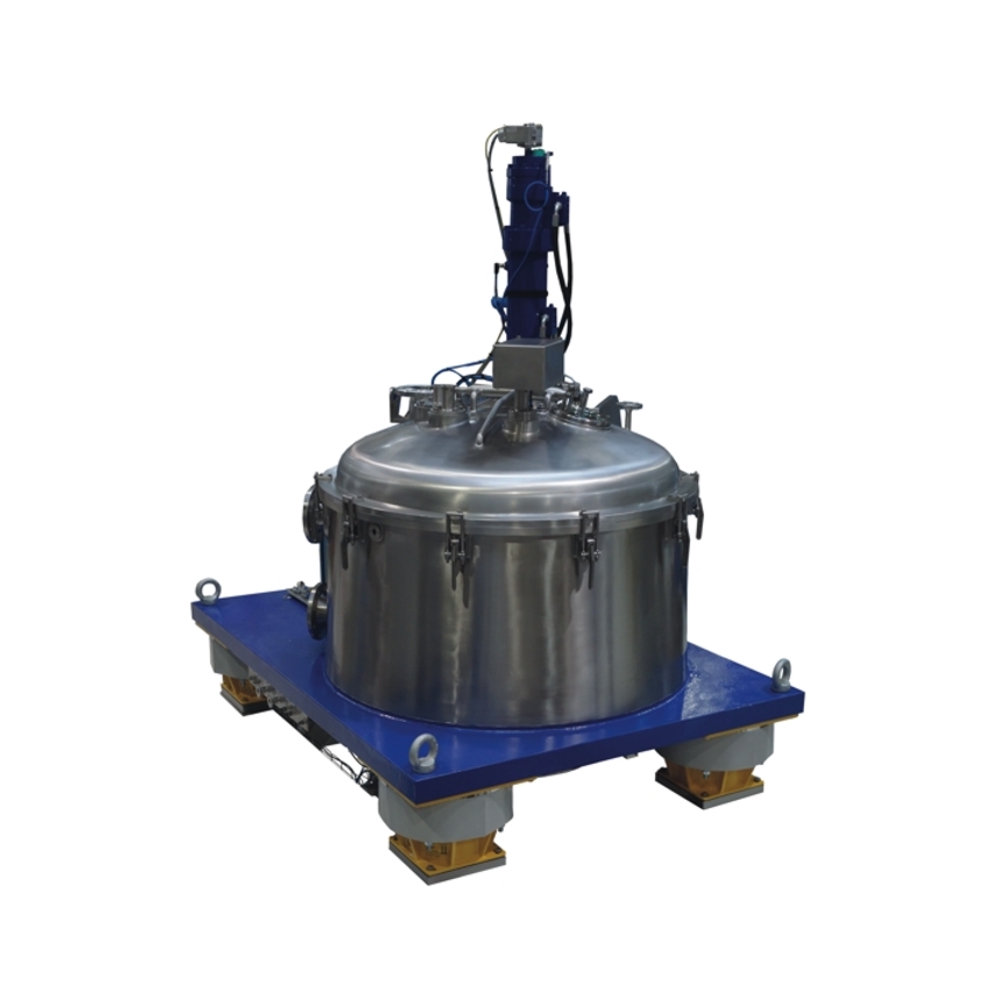

The HEINKEL Drying and Separation Group supplies industrial batch filtering centrifuges for the pharmaceutical, fine chemical and chemical industries, where solid-liquid separation takes place mechanically.

We specialize in tailoring our solution to meet the customer’s application needs.

The typical process includes filling, cake washing, spinning and unloading. One possible criteria of selection is based on the way to unload the solids, it characterizes the different design. It can be done:

- Manually by opening the lid and shoveling off the solids

see Vertical Top Discharge Industrial Centrifuge - Automatically by peeling off the cake and discharging through the bottom

see Vertical Bottom Discharge Industrial Centrifuge - Automatically by peeling off the cake in a horizontal axis centrifuge

see Horizontal Peeler Industrial Centrifuge - Automatically by inverting the filter cloth

see Inverting Filter Industrial Centrifuge

You can find the animation of all these processes in the dedicated product detail pages. Fore more information, please refer to the Product finder.

We can also offer centrifuges for special applications like:

- TiO2, abrasive powders > Classifying Centrifuges

- FGD-plants > Gypsum Centrifuges

- Small parts coating > Coating Centrifuges

- Oil recovery from chips > Vertical Pusher Centrifuges

Depending on the application, the centrifuges can include Ex-proof design and CIP/SIP features, several material of construction are available (from SS to Hastelloy, Titanium, etc.). See product detail pages for more information.