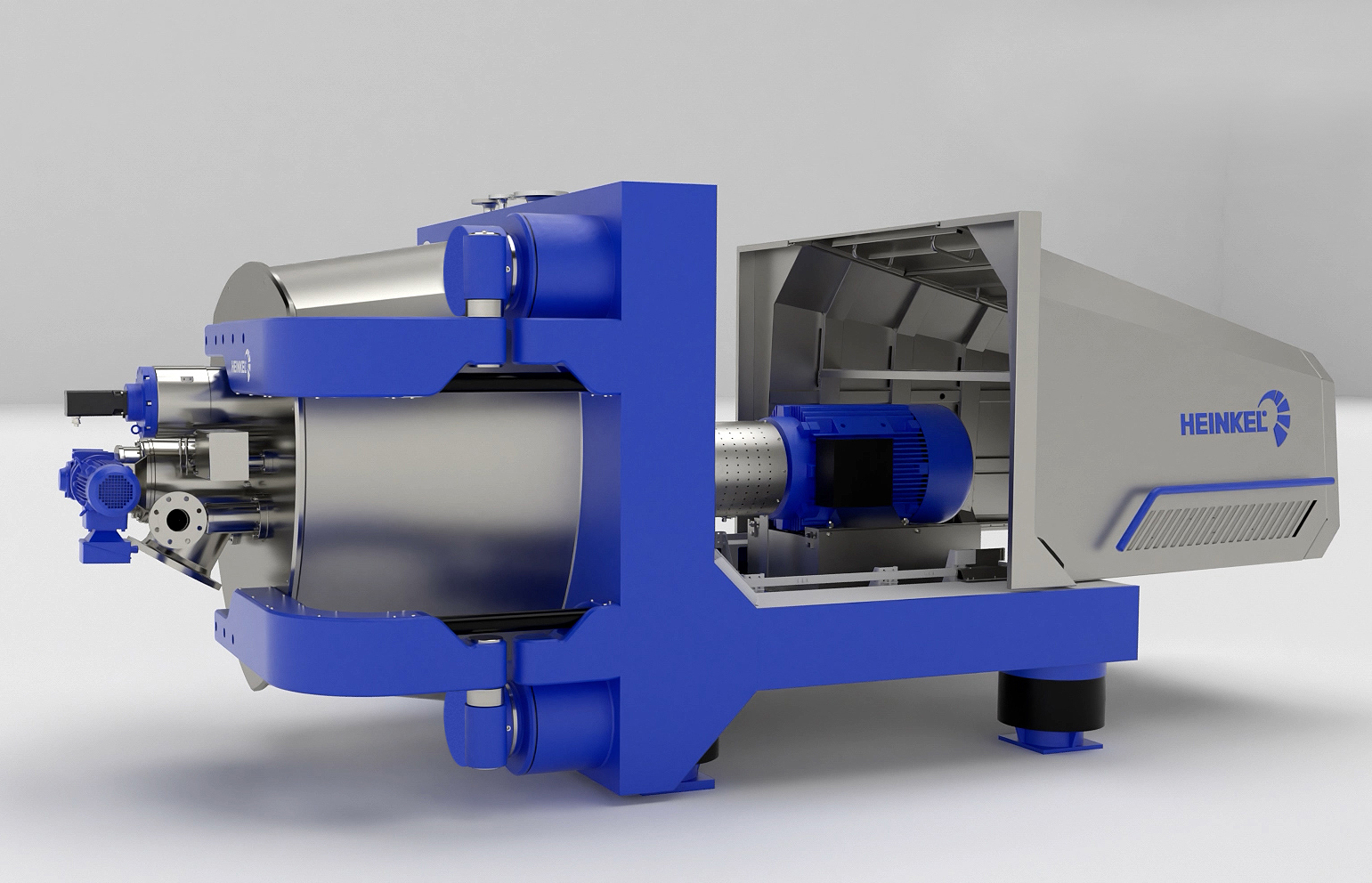

BOLZ-SUMMIX Cylindro Conical Dryer at POWTECH 2023: Highest product quality and a wide range of applications

As an industry expert in drying and mixing, BOLZ will be presenting select product highlights at POWTECH 2023, as well as its versatile Cylindro Conical Dryer CCD which meets almost any process requirement thanks to its high flexibility. With its flexible design, different agitators and material grades, the CCD from BOLZ-SUMMIX is an all-rounder. It can be adapted to almost any process requirement and can be used as vacuum contact dryer and evaporator as well as steriliser or alkalizer. The efficient Cylindro Conical Dryer is often used after mechanical solid-liquid separation but can also be operated without a preceding mechanical separation stage.

The products processed range from slurries and pastes to filter cakes, granulates and powders. It ensures highest quality and short drying times and achieves final moisture contents of just a few ppm, depending on the requirements. The different mixing unit designs such as helix, double helix, paddle or spiral segments make it a multi-purpose dryer.

For products, whose final moisture content should be as close to zero as possible, conventional drying systems reach their limits soon. BOLZ-SUMMIX fulfils these demanding requirements with its Cylindro Conical Dryer Type CCD, ensuring a gentle yet intensive mixing and short drying times without significant product wear debris. This is provided by the optimised agitator in combination with heated or non-heated mixing helix. The three-dimensional mixing continuously feeds new material to the heated vessel wall, thus ensuring a homogeneous temperature in the dryer. The heating of the complete dryer prevents the formation of cold spots and in addition to that, an insulating jacket keeps the heat inside the dryer and guarantees protection against contact at the same time.

For an increased throughput and gentle product drying at low temperatures, the Cylindro Conical Dryer is often used as a vacuum contact dryer. Due to negative pressure, the moisture evaporates at lower temperatures, which has a positive effect on the quality of the end and intermediate products. Moreover, throughput increases and energy losses are reduced. An intelligent cleaning concept, featuring WIP and CIP nozzles as well as cleaning of the vapour filter by means of jet cleaning, ensures maximum hygiene.