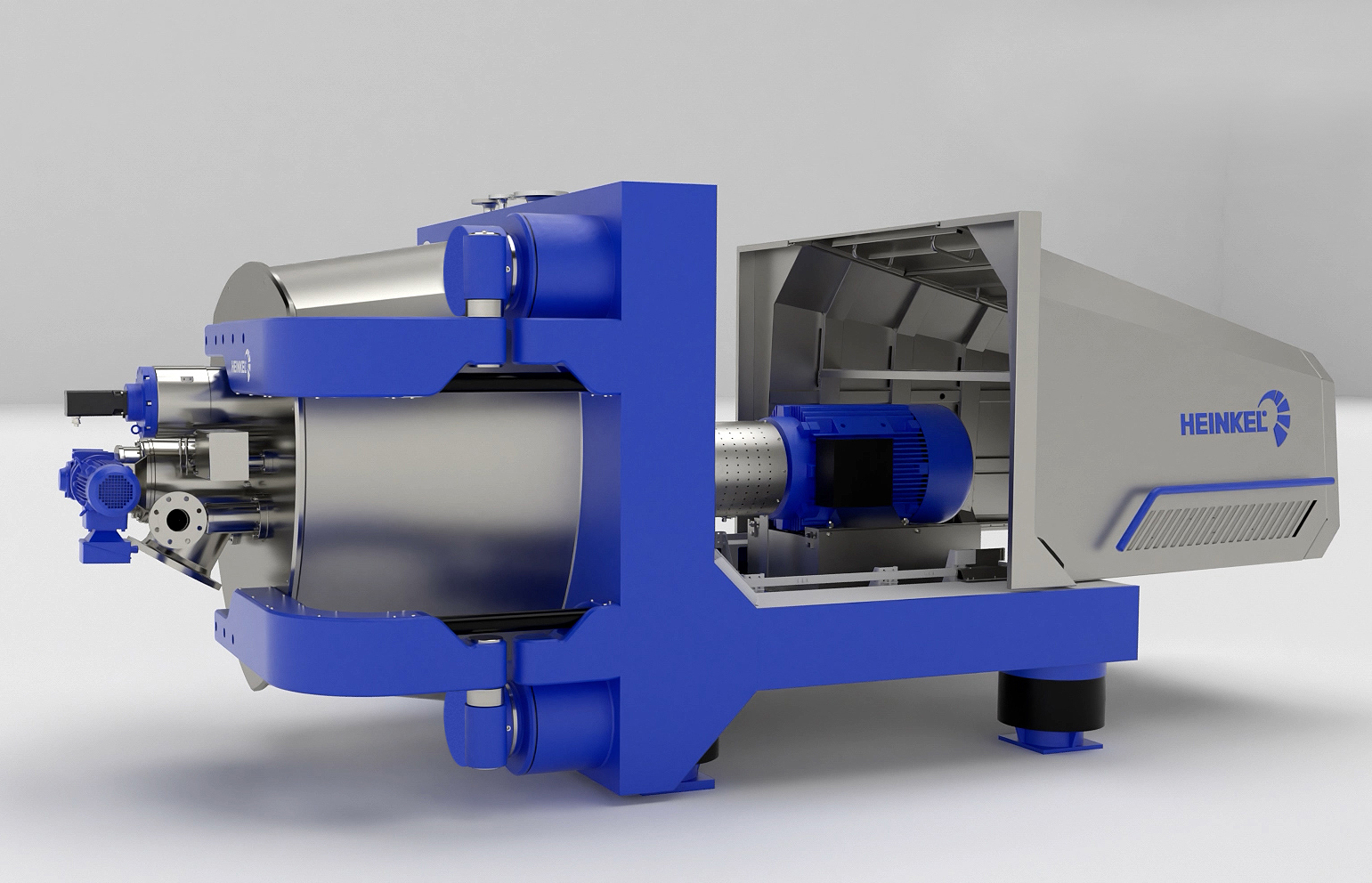

HEINKEL presents newly developed BLUETECTOR® peeler centrifuge at POWTECH 2023

With the new BLUETECTOR® machine generation, HEINKEL is introducing a peeler centrifuge with state-of-the-art process technology at POWTECH 2023, which has also been optimised from an ecological point of view. The industry specialist, which is also ISO 14001 certified, is thus meeting the increasing demands for environmentally friendly and energy-efficient solutions. At reduced energy consumption, the peeler centrifuge offers both maximum flexibility in processing a wide range of solids as well as excellent performance and product quality.

The user benefits from a possible energy saving of 50,000 kWh per year with the BLUETECTOR® peeler centrifuge. This is achieved by innovative, only electric drive concepts, reducing friction losses to a minimum while at the same time providing maximum flexibility. The drum drive is considerably more ecological and economical thanks to an optimised electric motor without belt drive. In combination with other electric drives, the concept ensures environmentally friendly processes in hazardous areas up to ATEX zone 1. The new BLUETECTOR® machine generation convinces with clean machine areas without hydraulic oil and drive belts.

The new BLUETECTOR® peeler centrifuge also achieves savings of up to 35 percent in terms of the amount of cleaning liquid. The cleaning with integrated CIP system runs fully automatically and requires a low flooding volume due to the patented housing shape. As a result, the BLUETECTOR® peeler centrifuge not only requires less cleaning liquid, but also correspondingly less filling time, which helps saving energy and reducing batch times.

The patented and optimised housing design enables simple filtrate drainage through the rear wall without any additional guidance for the liquid, thus additionally increasing the efficiency of the processes. The fully electric discharge process offers varible settings for a wide range of solids, also ensuring shorter batch times due to the improved process control. The slidable machine cover reduces noise emissions and increases cleanliness of the technical area as well as ease of maintenance.

With its new generation of machines, HEINKEL has succeeded in integrating professional design into the product development process. The BLUETECTOR® peeler centrifuge received the “Special Mention” award at the renowned international Design Award Baden-Württemberg, known as “Focus Open”, thus confirming the product development in international comparison.