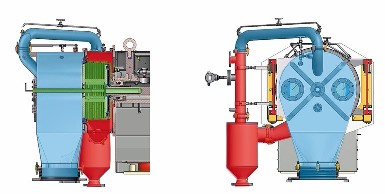

Cylindro Conical Dryer CCD with wide range of applications

The BOLZ Cylindro Conical Dryer CCD is an all-rounder. With its flexible design, different agitators and material grades, it can be adapted to almost any process requirement in the chemical, fine chemical, pharmaceutical and food industry. It is used as vacuum contact dryer and evaporator as well as steriliser or alkaliser, providing the highest quality […]