From product development to production: Flexible cylindro conical dryer CCD from BOLZ-SUMMIX at Achema 2024

Visitors at ACHEMA 2024 can experience innovative drying technology live at booth C49 in hall 6.0 of the industry specialist BOLZ-SUMMIX. From 10 to 14 June 2024, the expert will be showcasing its cylindro conical dryer CCD160 at the joint booth of the HEINKEL Drying and Separation Group. The CCD is highly flexible and suitable as a pilot system or production machine for a wide range of processes such as drying, evaporation, alkalisation and sterilisation.

BOLZ-SUMMIX is one of the leading experts for mixing and drying in the chemical, fine chemical, pharmaceutical and food industries, offering customised solutions – from kilo labs for product development to high-volume production machinery and systems.

Universal use for pilot tests, scale-ups and production

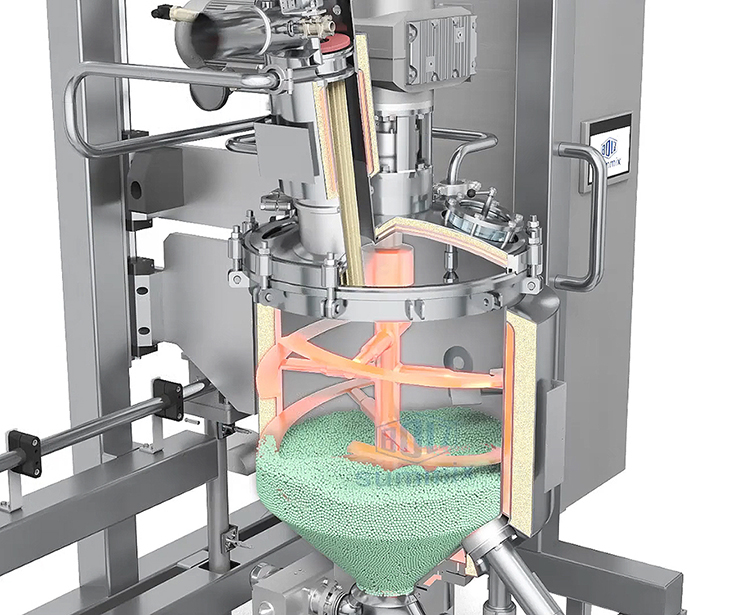

The cylindro conical dryer CCD160 is universally applicable as a vacuum contact dryer, evaporator, steriliser or alkaliser, providing the highest quality at short processing and drying times. Suitable for the interface between product development and production, it is used both in pilot labs and as a production machine for small quantities. The CCD ensures verified quality assurance for pilot trials and the optimisation of compounds, active ingredients and production procedures. For reliable scale-ups, it fulfils the basic requirements for a reproducible process in pilot scale. A variety of filling volumes, different materials from stainless steel to titanium as well as mixer designs such as helix, double helix, paddle or spiral segments make it a multi-purpose dryer.

Gentle drying for demanding products

With its cylindro conical dryer CCD, BOLZ-SUMMIX fulfils high quality requirements, especially for products whose moisture content should be as close to zero as possible. The intensive yet gentle mixing ensures short drying times without significant product wear debris. Drying can be performed at a very low pressure of less than 30 mbar absolute, and the final moisture content is just a few ppm, depending on the requirements. The CCD handles slurries, pastes, filter cakes as well as granules and powders and can also be operated without a preceding mechanical separation stage. The low process temperatures have a positive effect on the quality of the end and intermediate products, particularly when handling temperature-sensitive substances such as enzymes.

Sophisticated functionality

The central mixing helix as core technology of the cylindro conical CCD, is precisely adapted to the shape of the heated vessel. This allows a continuous product movement, thus ensuring a homogeneous temperature in the dryer. To reduce drying times, the mixing helix can also be heated. The CCD with its mobile machine design is also equipped with an insulating jacket, vacuum pump, heatable vapour filter with jet-cleaning, product sampling valve and control cabinet with integrated HMI.