Alkalising and drying of cocoa nibs with process reactors from BOLZ

As a luxury food, chocolate is indispensable for many people. However, it is a long way from an untreated, sour-tasting cocoa nib to delicious chocolate. A central step in this process is the alkalisation of cocoa nibs and the associated refinement of the precious raw material.

With its central shaft cooker/alkaliser of the CCM series, BOLZ offers a powerful and versatile process reactor for the alkalization and drying of cocoa nibs. This process includes operation under vacuum, use as an overpressure reactor, homogeneous mixing and sterilisation of the broken cocoa nibs.

With its sanitary contained design and its flexibility, the BOLZ central shaft cooker/alkaliser CCM meets the highest standards regarding product quality in combination with short reaction times and gentle product handling. This means that all process steps, such as heat treatment by adding steam directly into the reactor vessel, treating the cocoa nibs at overpressure and subsequent drying at negative pressure, can be carried out in one machine.

Production process of alkalised cocoa

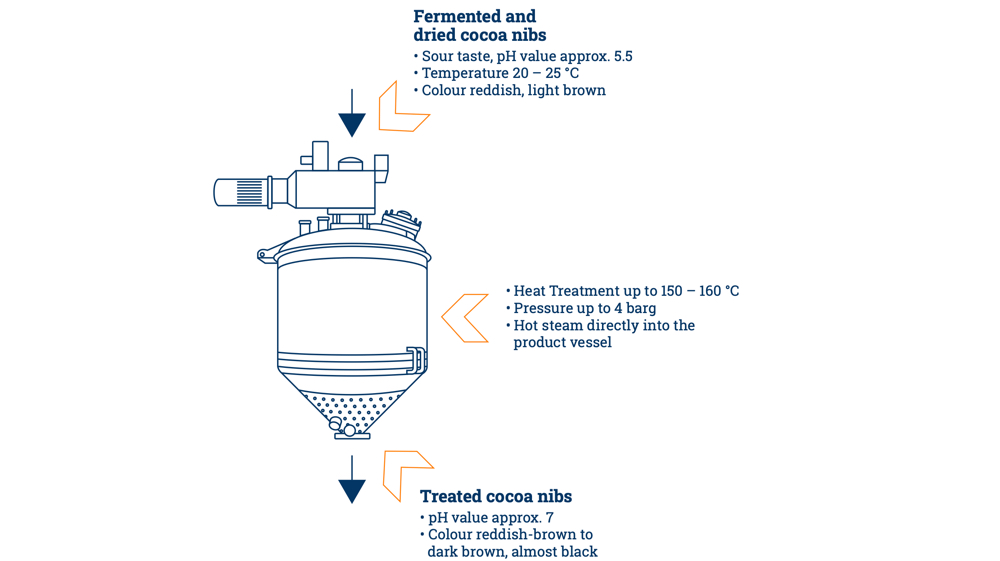

Alkalised cocoa is an ingredient used for example in chocolates, cakes, confectionery and beverages providing unique taste experiences. As the untreated cocoa beans are initially very sour after fermentation and do not have a good taste, they are broken into cocoa nibs and heated by the addition of steam. By means of overpressure and temperature, an alkaline solution is added, reducing the bitter flavouring components of the untreated cacao nibs and raising the pH value to approx. 7. Afterwards, the unwanted bitter substances have to be washed out and the colour of the cocoa has to be adjusted. A further process step includes the gentle and time-saving drying of the product in the same machine.

These machines are ideally suited for processing cocoa nibs

Filter your solution

To help find your product of interest we have developed this product finder. The product finder provides the possibility to filter on product group, specific product types, application and brand. The filters can be used separate and in combination.

Your benefits when processing cocoa nibs with BOLZ

Homogeneous alkalisation

by central mixing helix

Optimum product handling

by gentle, yet intensive mixing

Homogeneous heat distribution

during the reaction

Effective process

alkalisation and drying in only one machine

Optimum mixing

due to central mixing helix

Flexible processes

by means of vacuum and overpressure

Process reactors for the highest standards in food production

BOLZ-SUMMIX is a leading manufacturer of machinery and systems solutions in the fields of mixing and drying. The product portfolio ranges from small laboratory and test machines to large production plants. Well-known customers worldwide benefit from the high-quality, customised and completely executed mixing and drying systems as well as the comprehensive know-how of the employees. Our team of highly qualified specialists will guide the customers from the time when we first carry out tests in our laboratory or pilot plant systems to our customer-orientated engineering processes and the initial operation of the equipment or system.