HMI upgrades

Modern HMI control panels are extremely advantageous when it comes to accessing system data and visualizing different system parts, operating and maintenance interfaces on a single, user-friendly platform. You also benefit from faster inspection and maintenance thanks to the possibility of remote support, from faster delivery times for spare parts as well as from a reduction in faults, downtimes and costs.The state-of-the-art touch panel, which can also be operated with gloves, provides a high IP protection and enables the simple and fast incorporation of customer-specific functions.

Working platforms

Safe, fast and easy to install: Our working platforms for conical process vessels make repair and service work on reactors, orbital arm and cone screw dryers and mixers easier. Built to suit customer requirements and with a modular design, they are the ideal alternative to the complex and time-consuming assembly of scaffold or wooden working platforms.

Our platforms are of a stable aluminum construction, are TÜV-certified, CE-compliant and can be reused for many years.

Filter plates

We supply filter plates for all kinds of requirements regarding material and permeability. Whether fabric, such as cotton or polypropylene, insert filter elements made of metal, sintered multilayer filter plates or as a sterile configuration with the filter elements secured from below: Filter plates for filter dryers can be replaced easily and quickly.

Either the complete filter plate is replaced or, in the case of a repair, only segments – whatever you require, even with systems from other manufacturers.

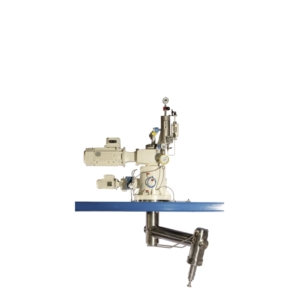

Ball segment valve

The Ball Segment Valve, BSV for short, is the result of an development of a innovative valve for pharmaceutical and fine chemical processes. For a wide range of solids applications, it is the preferred valve for process equipment like vacuum dryers, reactors or centrifuges as both as inlet and discharge valve.

Dust filter

We supply customized dust filters for dryers, mixers and reactors according to FDA, GMP and EU guidelines even in small batches.

We provide an entire range of different dust filters from simple filter bags made of polyester or PTFE including a support cage through full-fledged anti-static filter elements to complex pleated metallic fabric filter elements.

Containment systems

Containment systems (isolators, also glove boxes) allow for protected taking of samples, discharging of products, packaging the products in cladded barrels or other containers, the discharge of residual heel for a full product yield as well as filter cloth disposal whilst fully protecting the operating staff whereby at the same time a contamination of the product is avoided. The isolator is connected with the aid of a flange around the discharge stopper at the filter dryer.

Please find in the following further informations about our containment systems.

Mixing screws

For typical mixing applications made from regular stainless steel and special materials, we have just the right screws in our portfolio – raw, polished or, if required, electropolished, with the necessary coupling and guide, cylindrical or conical, as well as in a suitable sanitary design, if so required.

We supply our mixing screws as replacements or for re-equipping existing machines, even those from other suppliers.

Drive systems

We supply quickly exchangeable assemblies, such as gearboxes and orbital arms as replacements or for re-equipping your machines – both for products of the HEINKEL Drying and Separation Group and for other makes.

Our drive components meet the current guidelines of directives such as ATEX, CE, SIL or cGMP.

Sealing system for ball segment valve

High demands in terms of vacuum and pressure tightness are easy to achieve by retro-fitting our innovative sealing system in existing ball segment valves.

The special geometry of the inflatable seal enables long-term, reliable sealing against solid, liquid and gaseous media.

There is a wide range of seal materials available.

Upgrade of CIP systems

The variety of diverse products and applications demands different solutions for plant cleaning.

Our CIP systems focus on maximum hygiene with minimal downtimes.

This enables productivity and product quality to be secured equally. Regular upgrades optimize your production process and simplify cleaning

process validation.