Reliable horizontal peeler centrifuge with inerting system and state-of-the-art control concept

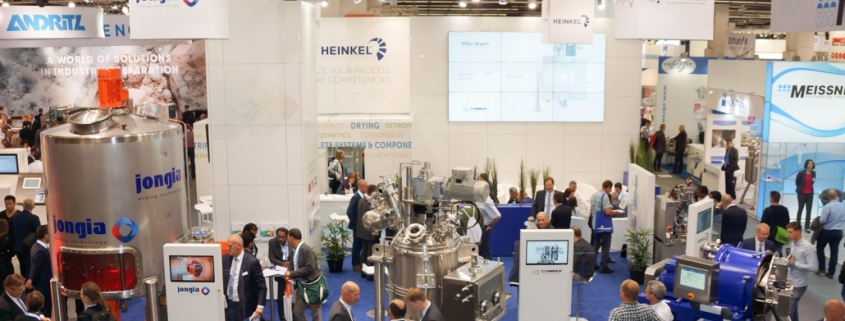

At POWTECH 2019, HEINKEL is presenting the H 630 C in compact design, a horizontal peeler centrifuge for chemical applications. Due to the reduced distance between the drive shaft and the support foundation, the centrifuge has considerably less weight and optimal vibration behavior.